What to Know When Buying Laser Cutters

Business owners review cutting tools according to affordability and function. Laser cutters help the business eliminate several tools and save the business owner money. The tools ensure that the workers have the right equipment for every job.

A Service Contract Is Helpful

The machines must be calibrated regularly and assessed. This doesn’t take a long time to complete, and the workers can perform the tests by following the instructions on the machine’s user screen. Service providers may offer calibration and maintenance for more complex laser cutters, and they will come to the business to complete the services for added convenience. A service contract could also give the business owner discounts on certain services.

The Machines Perform Quick Cuts

The laser cutters perform quick cuts and save the company invaluable time. The workers load the materials onto the cutter with ease and lock them into place. When they are ready to perform the cuts, the workers press the start button. The machine completes the cut, and the workers unload the materials safely. They won’t have to wait for the materials to cool since the machines don’t apply heat onto the materials. Business owners who want to learn more about the laser cutters read reviews of Boss laser Youtube right now.

The Database is Available at Any Time

The laser cutter machines have databases that offer ample storage for existing designs and room for new uploads as the business grows. The business owners can add extra designs at any time, and they can save all the projects they complete for their clients. It’s easier to repeat the orders if the designs are in the database. The business owners can use the database to review projects and make modifications at any time.

Repeat Cuts Are Easy

Repeat cuts are easy for the business since the designs are in the database, and they save time. The workers can load the materials and pull up the orders in minutes. Next, they just start the order and cuts according to the details saved for the client. This makes it simpler to complete ongoing projects for the same client, and if other customers like the design or pattern, the business could provide the same option for additional clients.

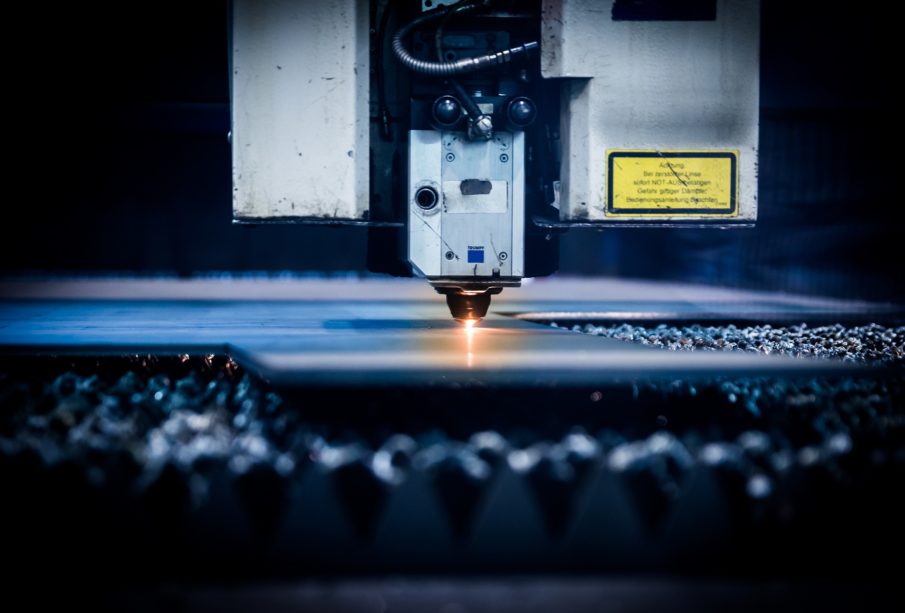

The Laser Won’t Touch the Materials Directly

The lasers never touch the materials directly, and they won’t cause any damage. The business owner won’t spend more money on extra materials just in case an error happens. The laser cutters eliminate common errors and issues that present problems for businesses. Laser cutters cut the materials and create smoother edges for business. Using the laser cutters saves money on materials and prevents the business from increasing overhead costs.

Businesses can get more by using laser cutters instead of traditional cutting tools. Saws, for example, produce jagged edges and could make it difficult to cut steel without imperfections. A laser cutter could eliminate these issues and create perfect edges. Business owners can learn more about the laser cutting tools by contacting a vendor now.