Boss Lasers: Oh, the Things You Could Do with Them

When most people think of lasers, the things that come to mind are mostly centered around industrial applications. It’s no secret that the uses of lasers by industrial entities are numerous. What many people aren’t aware of, however, is that industrial applications are not only a single focus of lasers, but they are only one of many.

What follows are just a few of the wide variety of applications for Boss Laser equipment. If you want to know more, check out boss laser facebook.

Marking and Etching

The last time you wanted to mark something, what did you do? If you are like most people, you probably used a marker or label of some sort. But what if there was a need for a permanent mark or something that was attractive that everyone could see and use? This is an application for lasers that has been used effectively for years in both industry and by hobbyists. It doesn’t matter whether the mark or etching is for.

In past years, sandblasting and similar techniques have been the best any hobbyist could do if they wanted to mark or etch a material, whether it be metal, glass, wood, or practically anything else. Nothing can even come close to the quality and accuracy that can be afforded by lasers.

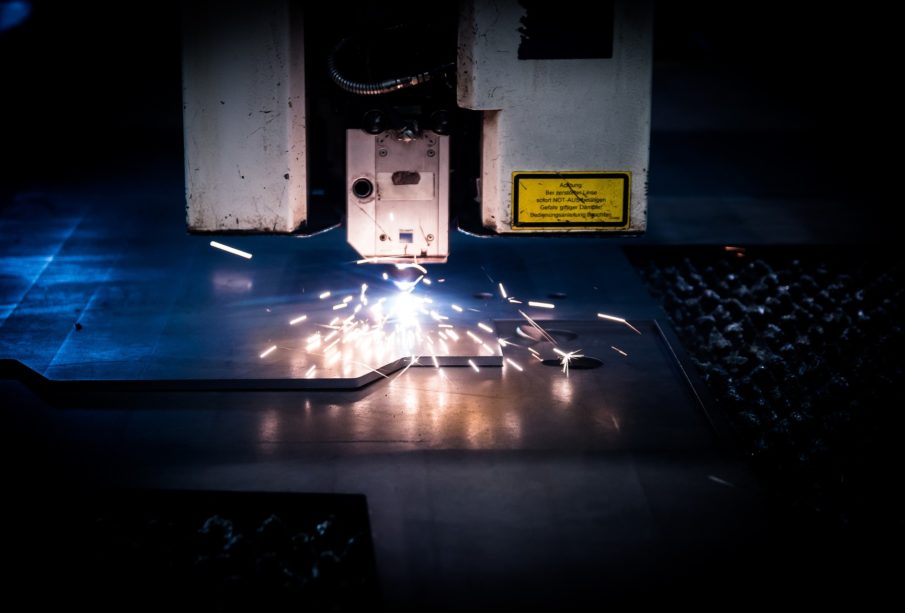

Cutting

Cutting is one application that has been used for years in both industrial and hobby uses of lasers. In no other cutting method can someone reach the level of accuracy and clean cuts that can be afforded by lasers. There is no such thing as offset when it comes to lasers either. The cut you want is the cut you get.

Suffice it to say the advantages of using lasers are numerous. This is true not only in terms of what lasers can do the effects of using lasers are far-reaching. These include:

- Cutting and etching are far more precise and patterns better maintained with lasers. There is no better way to cut or engrave a fine line than with a laser cutter or engraver.

- In terms of eco-friendliness, there is nothing better than a laser-cutter or engraver. Lasers save energy, don’t contain any toxic substances, and can adapt their use to practically any application.

- No other cutting or engraving method lends itself to saving materials and time better than lasers. There’s less waste and the utilization of material is far more advantageous with lasers than with any other type of material.

- Lasers do not deform materials as they are cut or engraved. Laser energy is concentrated on the precise point where it is needed and does not affect any of the surrounding areas.

- Laser cutters and engravers do not leave any sort of burr, and surface finishes are always smooth and there is little need for more finishing.

Oh, the things you can do with lasers, indeed. Whether a laser is being used by an industrial user or a hobbyist, the applications of lasers are limited only by the imagination of the person using them.